Process

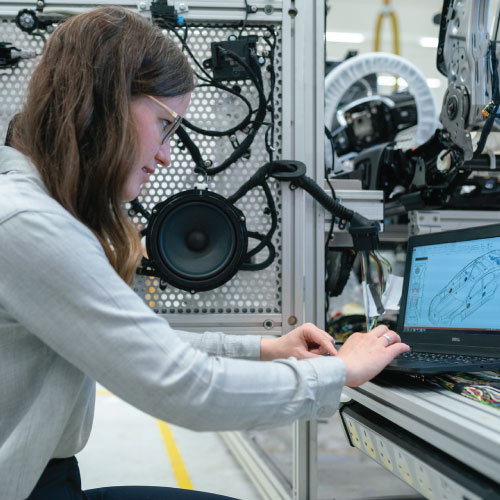

Production Capabilities

- Thermally bonded materials

- Thermal-forming (die design and stamping)

- Calendar rolling

- Needle-punched

- Virgin or recycled materials

- Synthetic or natural fiber blends

- Low denier capabilities for acoustic qualities

- Cutting/blanking for various roll/sheet sizes

- Multi-denier blending

- Laminating

- Scrim application

- Die cutting

Research & Development

Full Polymer Lab Capabilities

Fiberworx has extensive R&D capabilities with multiple full-time polymer PhD’s and technicians on staff. We have a team that will work with customers to assess individual needs, design around existing constraints, and engineer a low-cost/high-impact solution.

- Areal Density

- Bulk Density

- Thickness

- Moisture Content

- Filtration Testing

- Air Permeability

- Pore Size

- Porosity

- Pore Distribution and Structure

Quality

Our Policy

Fiberworx strives to exceed our customers’ expectations by providing best in class products on time and at a competitive price. We aim to meet all internal and external requirements of the standards. We accomplish this by continually improving our products and processes while providing a safe and clean environment for our employees.

In meeting our commitment, the Fiberworx facility obtained its certification to ISO 9001:2015 Quality Standards and continues to maintain their certification through semi-annual surveillance audits.

Quality Certificate Request

Fiberworx

Cleveland Industrial Innovation Center

17000 Saint Clair Ave.

Ste. 105

Cleveland, OH 44110

Get in Touch

Call: 216.767.4530

Email Us